5 Things to Know Before Buying TMT Steel Bars in India

When we think of steel, we usually imagine cars or appliances. However, steel is essential for the construction industry as well. In fact, the standards for strength and durability are often determined by their use in the industry. Steel is categorized into three main grades: mild, medium, and high-strength. Within these three broad categories lie numerous subcategories that indicate the specific strength required for different industries and materials.

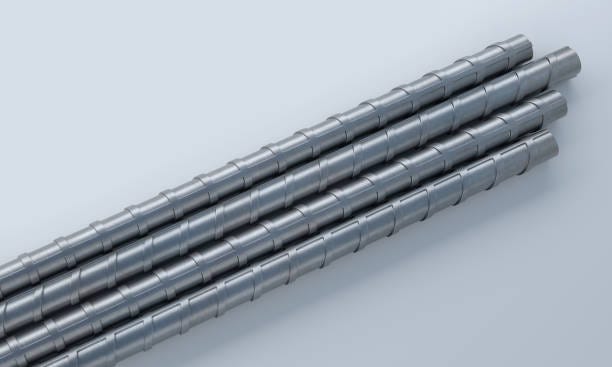

Over the past few years, the demand for TMT bars has exploded. Since they offer great strength and durability, you may find yourself wondering why they are becoming so popular. The answer is simple! They are used mostly in a number of roads, bridges, and pipelines by steel manufacturers in India that are being constructed all over the world. TMT steel bars offer strength that is about 125% more than mild steel. That’s why you should not shift your focus from this bar if you plan to use it for vital projects such as railway tracks and building pillars.

1) Corrosion Resistance

Corrosion resistance is one of the key parameters to consider when buying TMT steel bars for your project. If you are building a structure in an area prone to flooding or has high humidity, then the anti-corrosive properties of the bars will keep your structure safe and sound.

TMT bars can withstand corrosion, as they are made from high-quality materials that help them resist external elements like acidic soil, marine salts, and high moisture content in the air. They also have greater durability than other types of steel bars because they won’t rust or corrode easily.

2) Certification

The next thing to look for in TMT steel bars is certification. A good TMT bar will generally have BIS/ISO certification. It is always advisable to go for reputed brands over others as they even have bars that conform to international standards, which gives a clear sense of the reputation of the brand, its quality and longevity.

3) Flexibility

The flexibility of a building determines how it will stand up to stress and strain, and it can also increase its lifespan.

This is why you need to make sure that your building material has the right amount of flexibility. If you choose a material that isn’t flexible enough, then you could end up with cracks in your concrete construction.

Large cracks in concrete construction can compromise the safety and integrity of a building. TMT bars with optimum flexibility can reduce breakages due to high degree shocks, seismic tension, concrete permeability or creep movement. Reinforced concrete with galvanized TMT bars makes buildings stronger and more flexible. The resilient bars hold the structure intact.

4) Grade

The steel bar’s strength and quality are strongly influenced by its composition. Generally, a higher-grade steel bar is more durable and will withstand stress better than lower grades. In India, TMT steel bars are available in three grades: Fe 500 D, 550 D and 500 S. If you are planning to build a house or other structure in an earthquake-prone area, it is crucial that the rebar used has the highest possible grade.

5) Testing

Tensile strength testing is an important step in the buying process. It is a way to determine how the material will respond when you apply force to it, giving you an idea of its rigidity, tensile strength, yield quality, etc. It’s crucial that you look for a brand that has a laboratory and testing facility, so you can be sure to get the right quality checks before delivery.

Conclusion

For the sake of simplicity, I have categorized the things you should consider before buying TMT steel bars into five main sections. By keeping these things in mind, you will be able to make a better choice for your construction project.

Comments

Post a Comment